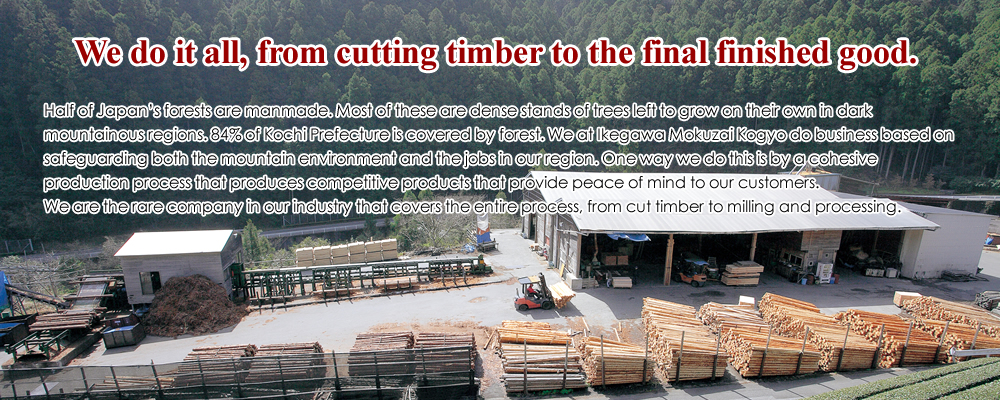

We cut and ship timber from the mountain forests and other land that we own. Efficient use of timber cut during forest thinning contributes to preserving forest environments.

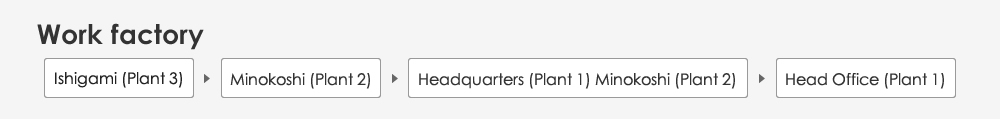

Transported logs are placed on a conveyor belt where they are debarked by machine and sorted by diameter.

High-precision sawing machines mill timber into boards and then adjust their length and cut them into smaller pieces.

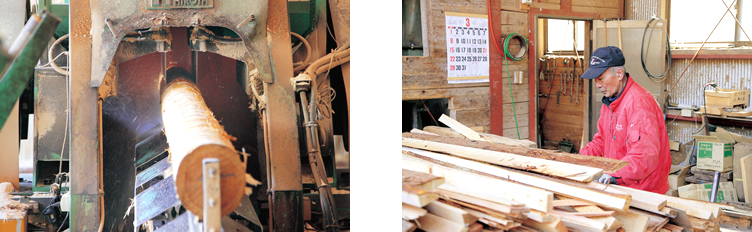

Sawing and milling timber produces chips, bark, and other byproducts. Wood is an outstanding and reusable organic resource derived from living things and not something to be thrown away. Wood pellets and chips can be converted to environmentally-friendly clean energy not just simply by combustion, so we reuse these materials as biomass drying fuel

and farming house heating fuel.

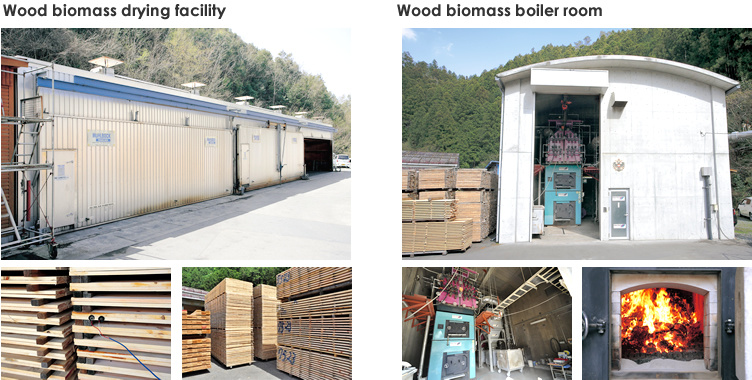

Our wood biomass drying facility computer monitors and controls moisture content around-the-clock.

Our boiler facility dries wood to provide a steady supply, while our wood biomass plant has achieved production of building materials of excellent quality. Our wood biomass plant uses equipment produced by Polytechnik Austria. The plant has maximum output of 1,500kw (equivalent to about 1.29 million kcal/h), and each of the plant's three machines can dry a volume equivalent to 50cubic metre of raw material.

The process retains color and aroma and does not damage fiber to preserve the inherent quality of the wood raw material.

Raw materials such as planer chips and sawdust that are unnecessary for pulverizing and drying processes are manufactured into relatively inexpensive and low-ash white pellet.

Dried lumber is planed to give it a nice appearance and texture.

Craftsmen carefully produce each piece of lumber, from milling to inspection.

With over 50 variations, drainboards form the core of a lineup catering to household and general goods and small accessories. We can also do custom order drainboards in quantities as little as one item. Ikegawa Mokuzai Kogyo is located upstream of the Niyodogawa, one of Japan's pristine rivers, so we make our wood products while carefully safeguarding the natural environment.

Producing low-cost get a (Japanese wooden clogs) in Vietnam back in the era when geta were Ikegawa's main item served as the opportunity for establishing a joint venture in 2015.

Today, our partner in Vietnam manufactures a variety of products,with an emphasis on products with higher production costs.

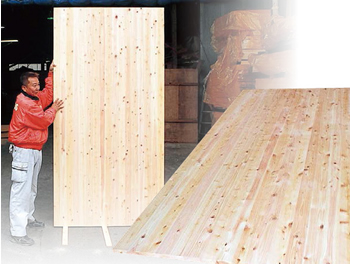

An innovative sheet panel process production line uses small diameter l umber to produce gorgeous panels with very few dead knots.

A costly low-temperature drying process produces a final product that retains the beauty, color, aroma, and unique attributes of the wood.

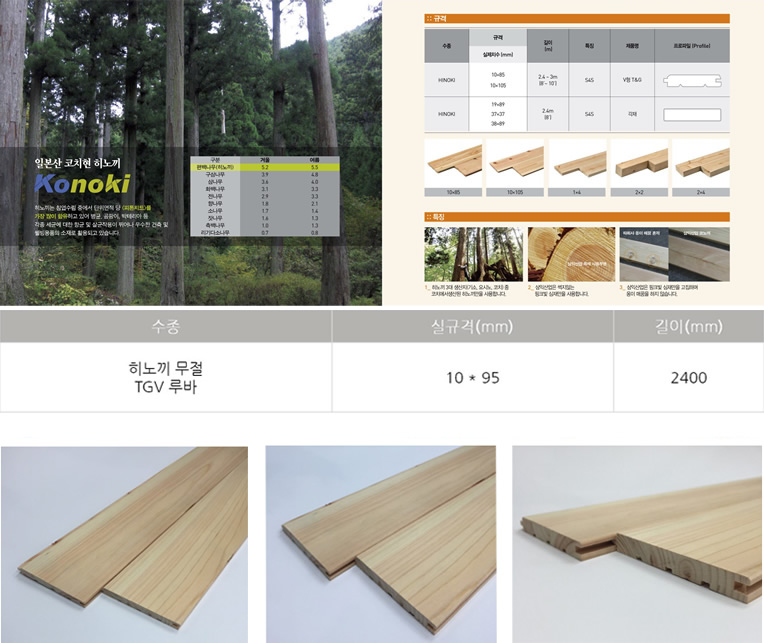

Kochi Prefecture cypress wood is manufactured into a processed laminated lumber developed for use in the interiors of condominiums and apartments in Korea. The production of laminated lumber started in 2009 and has developed into a brand especially for the Korean market. In 2014, our products exported to Korea received a Kochi Prefecture local industry award.

Kochi Prefecture cypress wood is manufactured into a processed laminated lumber developed for use in the interiors of condominiums and apartments in Korea. The production of laminated lumber started in 2009 and has developed into a brand especially for the Korean market. In 2014, our products exported to Korea received a Kochi Prefecture local industry award.